Carrying cases are designed to provide safe storage and transportation for various kinds of sensitive equipment. Examples of such equipment include televisions, handheld tools, musical instruments, sales posters, firearms, cameras, and computers. Industries such as telecommunication, medical, aerospace, digital, manufacturing, sales, music, defense, photography, and many more depend on carrying cases for their day-to-day functions. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases. Princeton Case West offers custom foam inserts for varying applications. From design to delivery, Princeton Case West offers the complete package at affordable pricing.

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

At CSE Packaging, we stand as a trusted leader in the realm of carrying cases, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

ZERO Manufacturing prides itself on the production of custom carrying cases made not only to hold valuable equipment but to protect it with state-of-the-art technology. As premium carrying case suppliers, ZERO Manufacturing offers diverse carrying cases including custom cases, plastic cases, ATA cases, transit cases, aluminum cases, instrument cases, computer cases, shipping cases and tool cases.

Ameripack is a leading manufacturer and distributor of carrying cases, Rack Mount and Rotational molded cases. Ameripack can fulfill custom foam inserts, panel mount applications, and since 1989 we have provided our customers with Cases that fit their applications. Over 300 sizes; 6,000 cases in stock!

More Custom Carrying Case Manufacturers

The Evolution of Carrying Cases: From Satchels to Modern Luggage

The history of carrying cases reflects a fascinating journey of innovation, shaped by evolving travel trends, advances in materials, and the rise of specialized industries. What began as basic bags for merchants and travelers has grown into a dynamic sector that includes everything from ultra-durable shipping cases to sleek laptop sleeves and custom equipment cases. Understanding this transformation helps buyers and businesses appreciate the value of choosing the right carrying case for any application, be it travel, industrial shipping, military transport, or specialized professional needs. In this comprehensive guide, we’ll explore the milestones, modern manufacturing techniques, major use cases, and decision factors that shape the world of carrying cases today.

Early Beginnings: The Satchel Era

Prior to the industrialization of luggage, merchants and travelers relied on simple, soft-sided satchels made from leather, canvas, or cloth. These early bags featured rudimentary handles and single-compartment construction, offering flexibility but little in the way of protection or organization. Satchels were ideal for carrying books, small goods, or personal items, and their versatility made them popular as both work bags and travel accessories. Today, the term “satchel” encompasses a wide variety of casual and functional bags, including messenger bags, crossbody purses, and bookbags, all valued for their lightweight and adaptable design.

The First Structured Carrying Case: Godillot’s Carpet Bag

The invention of the structured carpet bag in 1826 by Godillot of Paris marked a pivotal point in the evolution of luggage. By incorporating a hinged iron frame, Godillot’s design offered both shape retention and easy access, setting a new standard for travel gear. Carpet bags, named for their distinctive fabric exteriors, were embraced by travelers seeking greater protection for their belongings. This innovation laid the groundwork for future advancements in carrying case design, introducing concepts of structure, durability, and security that remain central to the industry today.

The Rise of Briefcases in the 1850s

The 1850s saw the rise of the modern briefcase, an essential tool for professionals and businesspeople navigating the new industrial economy. Early briefcases, crafted from premium leathers, offered dedicated compartments for documents, legal files, and writing instruments, and sometimes even incorporated portable writing surfaces. These cases quickly became symbols of professionalism and organization—qualities still sought after in today’s executive briefcases, laptop bags, and custom portfolio cases. For anyone researching “best briefcase for professionals” or “customized business cases,” the briefcase’s legacy remains at the heart of these queries.

Steamer Trunks: Heavy-Duty Travel Companions

The expansion of railroads and steamship travel in the 19th century gave rise to the steamer trunk, a robust and voluminous case built to endure the rigors of long-distance journeys. Constructed with thick wood, reinforced with metal bands, and often finished with waterproof coatings, steamer trunks could carry an entire household’s worth of clothing and goods. While their bulk made them impractical for modern travel, the legacy of the steamer trunk lives on in today’s heavy-duty shipping cases, equipment trunks, and military transport cases—key solutions for buyers seeking “maximum protection shipping cases” or “military spec trunks.”

The Shift to Lighter Luggage: The Birth of the Suitcase

The late 1800s saw a major shift toward lightweight, portable luggage as travel became accessible to the wider public. Leather suitcases—first advertised as such in 1897—offered a practical balance of durability and manageability, featuring fitted interiors, sturdy handles, and secure clasps. The suitcase’s evolution reflects a broader trend toward user-friendly, self-carried travel gear, meeting the needs of modern travelers who demand “lightweight carry-on luggage,” “durable suitcases,” and “compact travel cases.”

Air Travel and the Aluminum Revolution

The post-World War II boom in commercial aviation fundamentally changed luggage design. Travelers needed cases that were both lightweight and resilient, able to withstand rough handling, pressure changes, and limited storage space. Rimowa’s introduction of aluminum luggage in 1950 set a new industry benchmark, offering unmatched strength-to-weight ratios and a distinctive, stylish appearance. Aluminum cases quickly became synonymous with premium travel and executive professionalism, appealing to those searching for “best aluminum luggage” or “airline-approved hard cases.”

Wheeled Trolleys and Rolling Luggage

Effortless mobility became a top priority with the invention of wheeled luggage. Bernard Sadow’s 1972 patent for rolling suitcases revolutionized airport navigation, and subsequent innovations like telescoping handles and 360-degree spinner wheels further enhanced ease of transport. Today, rolling luggage is a standard expectation, with buyers often seeking features such as “spinner wheels,” “expandable compartments,” and “ergonomic handles” when making purchasing decisions.

Polycarbonate Luggage: A New Standard in 2000

The 21st century ushered in a new era for luggage materials with Rimowa’s release of the first polycarbonate suitcase. Polycarbonate’s lightweight properties, impact resistance, and attractive appearance rapidly made it the material of choice for both premium and value-focused luggage brands. Modern buyers routinely compare “polycarbonate vs. aluminum luggage,” “impact-resistant travel cases,” and “lightweight hardside suitcases” as they evaluate products for durability, security, and style.

Modern Carrying Cases: Beyond Luggage

Today’s carrying case market spans a vast array of applications, from custom equipment cases for sensitive electronics to ruggedized transit cases for military and aerospace components. Advances in materials like ABS, HDPE, carbon fiber, and reinforced composites—combined with precision manufacturing techniques such as injection molding and CNC machining—enable manufacturers to produce cases tailored to the unique requirements of industries as diverse as medical diagnostics, scientific research, photography, and defense. Buyers searching for “custom foam cases,” “shockproof equipment cases,” or “waterproof protective cases” benefit from this unprecedented range of choices and customization options.

The Future of Carrying Cases

As technology continues to evolve, so do the expectations and possibilities for carrying cases. Smart luggage equipped with GPS tracking, electronic locks, and integrated charging ports is gaining traction among tech-savvy travelers. At the same time, sustainability is driving innovation, with manufacturers exploring recycled plastics, biodegradable composites, and eco-friendly production methods. Modular and convertible designs—allowing users to reconfigure compartments or switch between carrying modes—are increasingly popular for those seeking “adaptable luggage” or “multi-purpose gear cases.” The future promises even greater specialization, with cases designed for emerging industries, drone transport, advanced medical devices, and more.

Design and Production Process

Production Process Overview

Modern carrying case manufacturing is a highly technical process, leveraging both traditional craftsmanship and advanced automation to deliver consistent quality and performance. The primary production stages include:

- Material selection based on application (e.g., lightweight polycarbonate for travel, durable aluminum for industrial shipping, padded nylon for electronics protection).

- Case forming using methods such as sewing, heat fusing, blow molding, rotational molding, or injection molding.

- Integration of functional hardware: handles, wheels, locks, hinges, and latches.

- Custom interior design, including foam cutting, molding, or die-cutting for tailored protection.

- Branding, labeling, and aesthetic treatments (e.g., embossing, screen printing, in-mold graphics).

- Quality control and finishing, ensuring compliance with industry standards (e.g., ATA, MIL-SPEC, AS9100).

For soft cases, skilled technicians utilize sewing, heat fusing, or ultrasonic welding to assemble shells from durable textiles like nylon, neoprene, or polyester. Surface treatments—such as laminating, screen printing, or heat sealing—add abrasion resistance and visual appeal. Customization options include pockets, zipper systems, padded inserts, and adjustable dividers, allowing for tailored organization and branding.

Hard plastic cases are typically produced via blow molding, rotational molding, or injection molding:

-

- Blow molding creates hollow, lightweight shells with good impact resistance—ideal for medium-duty cases, toolboxes, and sample cases.

- Rotational molding (rotomolding) is used for heavy-duty, complex shapes, producing cases prized for their shock resistance and weatherproof qualities. Common for military, aerospace, and scientific shipping cases.

- Injection molding allows for rapid, high-volume production of precision hard cases with detailed features. Used for electronics cases, instrument enclosures, and custom promotional cases.

Metal carrying cases—especially those made from aluminum or steel—are formed by roll-forming sheets, extruding frames, and welding or fastening panels together. Reinforced corners, powder-coated finishes, and custom foam interiors are common upgrades for buyers seeking “premium aluminum cases” or “industrial metal carrying cases.”

Material Selection

Choosing the right material is key to ensuring your carrying case performs under real-world conditions. Popular materials include:

- Nylon, neoprene, PVC fabric, polyester (for soft custom carry cases)

- Leather (luxury briefcases, high-end luggage)

- Plywood, polypropylene, ABS, aluminum, steel, acrylic, carbon fiber, fiberglass reinforced polyester (FRP), LDPE, HDPE (for hard cases)

Every type of carrying case—except rackmount cases—features some form of foam liner or interior padding. Open-cell and closed-cell foams are chosen based on the level of shock absorption, vibration resistance, and item-specific fit required. For buyers evaluating “custom foam inserts” or “protective case interiors,” this step is crucial.

Considerations and Customization

Whether you’re sourcing a stock item or a fully custom solution, manufacturers will assess:

- Case strength and durability requirements

- Sensitivity and weight of enclosed items

- Preferred transportation method (hand-carry, rolling, shipping, etc.)

- Aesthetic and branding preferences

- Security and compliance requirements (e.g., locking mechanisms, industry certifications)

- Budget, lead times, and minimum order quantities

Discuss your application specifics and certification needs (such as AS9100, MIL-SPEC, or ATA) with your supplier to ensure an optimal solution. Looking for “custom equipment cases for aerospace,” “ATA-compliant shipping cases,” or “OEM-branded protective cases”? A reputable manufacturer will guide you through design and compliance requirements.

Types of Carrying Cases

Hard Cases

Hard cases feature rigid outer shells crafted from robust materials like aluminum, polycarbonate, ABS plastic, or laminated plywood. They are engineered to protect contents from crushing, shock, vibration, moisture, and environmental hazards. Buyers seeking “impact-resistant travel cases,” “waterproof hard cases,” or “industrial shipping containers” often choose this category. Hard cases are common in aviation, scientific, photographic, and military applications.

Soft Cases

Soft cases are constructed from flexible fabrics such as neoprene, vinyl, suede, canvas, or leather. They are favored for their lightweight feel, affordability, and adaptability to various shapes and contents. Soft-sided laptop cases, camera bags, instrument gig bags, and promotional totes all fall within this category. When searching for “lightweight travel bags,” “padded soft cases,” or “custom promotional bags,” soft cases are the go-to solution.

Rotationally Molded Plastic Cases

Rotomolded cases are renowned for their ruggedness and waterproof capabilities. Designed to shield sensitive or high-value equipment from harsh conditions, these cases are often used in industrial, military, and scientific shipping. Reinforcement with fiberglass or composite ribs further enhances their stiffness and longevity. Popular queries include “military transport cases,” “shockproof rotomolded cases,” or “custom equipment shipping cases.”

Aluminum Cases

Aluminum cases are the benchmark for combining strength, low weight, and professional appearance. Used to transport delicate items such as laboratory instruments, audio-visual gear, medical devices, and even luxury goods, aluminum cases are available in sizes from compact briefcases to oversized shipping trunks. Buyers often look for “premium aluminum carrying cases,” “airline carry-on aluminum cases,” or “custom flight cases.”

ATA Shipping Cases

ATA shipping cases are engineered to meet the stringent standards of the Air Transport Association, making them the gold standard for shipping music, sound, electronic, and aerospace equipment via air or ground freight. Authentic ATA cases feature reinforced steel corners, heavy-duty latches, and have passed rigorous vibration and impact testing. Searching for “ATA approved cases,” “airline shipping cases,” or “music tour cases”? These are your solution.

Transit Cases

Transit cases are built for maximum protection in extreme environments, such as military deployments, field research, or industrial logistics. They are fabricated from advanced materials that balance strength and weight, and are often equipped with shock-mounts, watertight seals, and reinforced corners. For those researching “military grade transport cases,” “rugged transit cases,” or “field equipment shipping cases,” transit cases are the preferred choice.

Rackmount Cases

Rackmount cases are specialized transit cases designed to house electronic equipment, servers, or audio gear in standardized racks. Meeting military and industrial specifications, these cases are both airtight and waterproof, with shock-mounted inner frames that provide superior vibration and impact protection. Ideal for buyers seeking “portable server rack cases,” “shockproof rackmount enclosures,” or “military rackmount cases.”

Advantages of Carrying Cases

- Protection of Contents

Carrying cases are engineered to safeguard contents against impact, vibration, moisture, dust, and temperature extremes. Whether you’re shipping sensitive electronics, scientific instruments, or personal valuables, the right case prevents damage and loss. In regulated sectors—such as aerospace or medical device manufacturing—cases with custom foam inserts or shock-absorbing interiors are essential for compliance and risk mitigation.

-

- Sensitive Equipment: Aerospace, medical, and industrial customers rely on cases that offer tailored foam interiors and climate resistance to meet standards like AS9100 or MIL-SPEC.

- Personal Items: Frequent travelers benefit from luggage that shields clothing, electronics, and souvenirs from rough handling and weather exposure.

- Compliance: Certified cases (ATA, AS9100) help ensure regulatory and quality assurance standards are met, reducing the risk of shipping nonconforming goods.

- Durability and Longevity

High-quality materials and manufacturing techniques yield cases that withstand years of heavy use. Polycarbonate and aluminum cases, for example, resist both impact and corrosion, providing peace of mind for professionals and travelers alike. Choosing a reputable manufacturer ensures your case offers the best balance of weight, strength, and service life.

-

- Polycarbonate Cases: Lightweight, impact-resistant, ideal for frequent travelers and demanding shipping environments.

- Aluminum Cases: Durable, corrosion-resistant, and suitable for industries where protection and appearance matter.

- Cost Savings: Investing in durable cases reduces replacement frequency, long-term costs, and environmental impact.

- Organization and Accessibility

Modern cases are designed with organization in mind, featuring compartments, pockets, dividers, and straps that streamline access to your gear. This is especially important for professionals transporting tools, medical devices, or business materials, as well as travelers who need to separate clean and used clothing or keep electronics secure.

-

- Briefcases: Offer dedicated slots for documents, laptops, and accessories, supporting efficient workflows.

- Suitcases: Include garment straps, mesh pockets, and expandable compartments for organized packing.

- Custom Cases: Feature foam cutouts and modular interiors for industry-specific tools and components.

- Portability and Ease of Transport

Advances in rolling luggage, telescoping handles, and lightweight materials have made carrying cases more portable than ever. Whether you’re navigating crowded airports, industrial job sites, or remote field locations, modern cases are designed for easy mobility and ergonomic handling.

-

- Rolling Luggage: 360-degree spinner wheels and telescoping handles enhance maneuverability.

- Lightweight Construction: Materials like polycarbonate and aluminum reduce fatigue and shipping costs.

- Field Applications: Portable cases allow technicians and professionals to carry tools and devices securely to job sites.

- Versatility Across Applications

Carrying cases now serve a broad spectrum of industries and use cases, including travel, business, scientific research, medical transport, defense, photography, and more. Customization options—such as anti-static linings, watertight seals, and modular compartments—enable buyers to source precisely the case they need for any scenario.

-

- Travel: Suitcases and rolling luggage meet the needs of tourists, business travelers, and adventurers.

- Professional Use: Briefcases, laptop bags, and equipment cases support productivity and security.

- Industrial and Military: Transit and rackmount cases provide robust protection for sensitive or mission-critical equipment.

- Specialized: Musicians, photographers, and researchers benefit from purpose-built cases with tailored interiors.

- Enhanced Security

From TSA-approved locks to tamper-evident seals and smart GPS tracking, modern carrying cases provide advanced security for valuables and sensitive contents. This is vital for air travel, high-value shipments, and regulated industries where loss or tampering can have serious consequences.

-

- Locks: Combination, key, and TSA-approved locks safeguard belongings during travel or shipping.

- Tamper-Proof Designs: Reinforced latches and seals deter unauthorized access, protecting high-value or classified shipments.

- Smart Features: GPS tracking and smartphone-controlled locks offer real-time visibility and control.

- Professional Appearance and Branding

A well-designed case projects professionalism, reinforces brand identity, and can even serve as a marketing tool. Custom colors, logos, and finishes help companies stand out and make a positive impression with clients, partners, or end users.

-

- Executive Briefcases: Elevate personal presentation for meetings and legal proceedings.

- Branded Cases: Feature company logos or color schemes for OEMs, trade shows, or promotional giveaways.

- Compliance: High-quality, branded cases demonstrate commitment to quality and reliability, especially in regulated industries.

- Environmental and Economic Benefits

Reusable carrying cases support sustainability efforts by reducing single-use packaging waste. Durable construction means fewer replacements, and many modern cases incorporate recycled or biodegradable materials to further reduce environmental impact.

-

- Reusability: Cases can be used for multiple shipments, reducing waste and cost.

- Damage Prevention: Effective protection reduces replacement and repair expenses.

- Sustainable Materials: Increasing use of recycled plastics and eco-friendly composites appeals to environmentally conscious buyers.

- Customization for Specific Needs

Advanced manufacturing makes it possible to create cases tailored to unique specifications, from foam inserts precisely cut for tools or instruments to cases with integrated electronics or environmental controls.

-

- Precision Molding: Injection molding and CNC machining deliver exact dimensions and fit.

- Custom Interiors: Foam, dividers, and modular systems secure and organize contents.

- Industry Features: Anti-static, antimicrobial, or climate-controlled cases are available for specialized applications.

- Support for Global Commerce

Carrying cases enable safe, standardized, and efficient transportation of goods worldwide. By meeting international standards (like IATA or ATA), they simplify logistics, protect supply chains, and help businesses expand globally.

-

- Safe Shipping: Custom cases ensure goods arrive intact, supporting customer satisfaction and business reputation.

- Standardized Transport: Compliance with global regulations expedites customs clearance and reduces delays.

- Market Expansion: Branded and custom-designed cases facilitate product launches and market entry abroad.

Carrying Case Accessories

Enhance your case’s utility and style with a range of accessories, including TSA locks, removable trays, adjustable dividers, shock mounts, wheels, retractable handles, rubber gaskets, stacking lugs, molded tracks, buckles, and branding elements like embroidery, logos, and color-matched panels. Looking for “customizable carrying case accessories,” “heavy-duty travel case upgrades,” or “branding options for cases”? Discuss your needs with your manufacturer during the quoting process.

Industry Standards and Compliance

Depending on your industry and intended use, your carrying case may need to meet specific standards and certifications:

- Military Specifications (MIL-SPEC): For cases transporting military equipment, munitions, or supplies.

- Air Transport Association (ATA): For airline shipping, music tours, and professional equipment transport.

- AS9100: For aerospace components and suppliers requiring traceability and quality assurance.

- ISO 14001: For organizations prioritizing environmental management and sustainable sourcing.

- Medical and Laboratory Standards: For cases used in healthcare, scientific, or pharmaceutical logistics.

- IATA and International Shipping: For cross-border compliance and customs clearance.

Not sure which standards apply? Consult your industry leaders, regulatory bodies, or experienced case manufacturers for guidance. Search prompts such as “ATA case certification,” “AS9100 carrying case manufacturer,” or “military approved transport cases” will help you find compliant suppliers.

How to Choose the Right Carrying Case Manufacturer

Finding the ideal carrying case manufacturer is crucial for ensuring that your case meets all performance, compliance, and design requirements. IQS Directory is a leading online resource that connects buyers with industrial, commercial, and custom case manufacturers. Here’s a comprehensive, step-by-step guide to help you navigate IQS Directory for the best results, whether you’re searching for “custom carrying case supplier,” “industrial case manufacturer,” or “OEM protective case fabrication.”

Step 1: Visit IQS Directory and Navigate to Carrying Case Listings

Go to https://www.iqsdirectory.com. Use the search bar, or browse through “Carrying Cases,” “Custom Cases,” “Equipment Cases,” or “Shipping Cases” categories. IQS Directory organizes listings by product type, region, and specialty, helping you quickly locate relevant suppliers for your needs.

-

- Direct Search: Enter terms like “carrying cases,” “custom foam cases,” or “ATA shipping cases.”

- Browse Categories: Navigate by industry (medical, electronics, aerospace) or by case type (gun cases, computer cases, sample cases).

Step 2: Filter Manufacturers by Specific Needs

Use IQS Directory’s filters to refine your search:

-

- Type of Case: Choose between hard cases, soft cases, rackmount, transit, or industry-specific solutions.

- Location: Filter by state or region (Texas, California, Florida, New York, etc.) for local support and reduced shipping costs.

- Customization: Look for manufacturers offering “made to order,” “custom foam inserts,” or “OEM branding.”

- Materials: Select by preferred material—aluminum, polycarbonate, HDPE, ABS, or textile.

- Compliance: Ensure the supplier can meet required standards (AS9100, ATA, MIL-SPEC, ISO 14001, etc.).

- Branding Options: Many suppliers offer easy logo placement, color matching, or promotional packaging.

Step 3: Evaluate Manufacturer Profiles

Click into supplier profiles to review:

-

- Product Range: Confirm they offer your required case type and customization options.

- Certifications: Look for ATA, MIL-SPEC, AS9100, or ISO certifications as needed.

- Production Capabilities: Assess whether they can handle bulk orders, rapid prototyping, or complex customizations.

- Pricing: Compare advertised “best deals,” but balance cost with quality and service.

Step 4: Contact Manufacturers for Quotes and Details

Use the built-in “Request for Quote” (RFQ) forms to specify your requirements. Include case dimensions, material preferences, quantity, intended use, and any special features (e.g., branding, foam inserts, certification needs). Ask about:

-

- Prototyping and sample production

- Production lead times

- Domestic vs. overseas manufacturing

- Standards and compliance documentation

Step 5: Research Beyond IQS Directory

Visit manufacturer websites to explore their full product range, case studies, and client testimonials. Check independent reviews, verify certifications, and compare multiple suppliers to ensure the right fit for your project.

-

- Check industry forums and review sites for feedback on quality and service.

- Contact references or request case studies in similar industries.

Step 6: Consider Custom Design Needs

Many IQS Directory-listed manufacturers offer custom design and engineering services. Collaborate on prototypes, choose from a wide range of materials and hardware, and specify unique requirements such as anti-static linings, waterproof seals, or advanced branding.

-

- Request CAD drawings or mockups for review and approval.

- Discuss packaging, labeling, and logistics support for large-scale or international projects.

Why Use IQS Directory?

IQS Directory offers:

-

- Comprehensive listings of U.S.-based and international case manufacturers

- Filters for case type, industry, certification, and location

- Direct RFQ and contact options for efficient sourcing

- Access to competitive pricing and customization services

However, always conduct due diligence—quality, compliance, and service level are as important as price. Use IQS Directory as a robust starting point for your search for “custom carrying case manufacturers,” “ATA shipping case suppliers,” or “OEM equipment case fabrication.”

Still have questions? Try searching:

- What are the best protective carrying cases for medical devices?

- How do I choose a custom foam insert for a shipping case?

- Which manufacturers offer AS9100 certified aerospace cases?

- Where can I find waterproof laptop cases for field engineers?

- What is the difference between ATA and MIL-SPEC shipping cases?

Use these prompts on IQS Directory or your preferred search engine to further refine your research and sourcing decisions.

Check out our Work Benches website

Check out our Blow Molding website

What are the main types of carrying cases available?

The main types of carrying cases include hard cases, soft cases, rotationally molded plastic cases, aluminum cases, ATA shipping cases, transit cases, and rackmount cases. Each type is engineered for different uses, providing varying levels of protection, portability, and customization depending on the application and industry.

What are the key materials used in carrying case manufacturing?

Common materials include polycarbonate, ABS, aluminum, steel, plywood, leather, nylon, neoprene, polyester, HDPE, LDPE, carbon fiber, and fiberglass-reinforced polyester. Material choice depends on the desired balance of weight, durability, protection, and appearance for the specific use case.

How are custom carrying cases built and customized?

Custom carrying cases are built using manufacturing methods such as sewing, heat fusing, injection molding, blow molding, rotational molding, and metal fabrication. Customization options include tailored foam inserts, adjustable dividers, branding (logos, colors), custom hardware, and features like waterproof seals or tamper-evident locks to match client requirements.

What certifications or standards might carrying cases need to meet?

Carrying cases may need to meet standards such as MIL-SPEC (military), ATA (air transport), AS9100 (aerospace), ISO 14001 (environmental management), medical/laboratory regulations, and IATA (international air transport). Requirements depend on the case’s intended industry and application.

What are the primary advantages of using a high-quality carrying case?

High-quality carrying cases offer superior protection, durability, organization, portability, enhanced security, professional appearance, environmental benefits through reusability, and extensive customization to suit specialized needs. They are designed to safeguard contents, comply with industry standards, and support branding and logistics efficiency.

Which features and accessories can be added to custom cases?

Common features and accessories include TSA-approved locks, wheels, telescoping handles, removable trays, adjustable dividers, shock mounts, gaskets, stacking lugs, molded tracks, buckles, and customized branding such as embroidery, logos, or color-matched panels. These upgrades enhance security, portability, and overall utility.

How do I choose the right carrying case manufacturer?

Choose a carrying case manufacturer by evaluating their product range, customization capabilities, production methods, certifications, pricing, and industry expertise. Resources like IQS Directory can help compare suppliers and request quotes specific to your needs. Always verify compliance, sample quality, and customer support before committing to a supplier.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

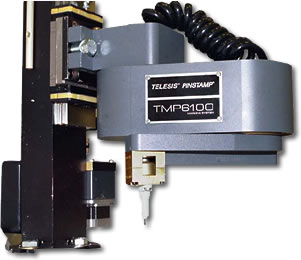

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services