Choosing the material for a custom case is an important decision and there are many options for the customer to pick from including plastics such as high density polyethylene (HDPE), fiberglass reinforced polyester (FRP), carbon fiber, rotationally molded polyethylene or linear low density polyethylene (LLDPE), aluminum, leather, glass, nylon, neoprene, polyester, steel, acrylic, wood and more. In general, cases can be broken into two groups: hard and soft. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases. Princeton Case West offers custom foam inserts for varying applications. From design to delivery, Princeton Case West offers the complete package at affordable pricing.

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

At CSE Packaging, we stand as a trusted leader in the realm of carrying cases, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

ZERO Manufacturing prides itself on the production of custom carrying cases made not only to hold valuable equipment but to protect it with state-of-the-art technology. As premium carrying case suppliers, ZERO Manufacturing offers diverse carrying cases including custom cases, plastic cases, ATA cases, transit cases, aluminum cases, instrument cases, computer cases, shipping cases and tool cases.

Ameripack is a leading manufacturer and distributor of carrying cases, Rack Mount and Rotational molded cases. Ameripack can fulfill custom foam inserts, panel mount applications, and since 1989 we have provided our customers with Cases that fit their applications. Over 300 sizes; 6,000 cases in stock!

More Custom Case Manufacturers

Hard custom cases have rigid outer shells that offer increased protection against crushing and can be waterproof whereas soft cases are flexible and cheaper. While many manufacturers provide stock sizes for items with standard dimensions such as television screens, computers or photography equipment, industrial designers and engineers also fulfill requests for custom cases created for specific items such as specialty tools, medical instruments or electronics.

Though custom sizes and shapes are available, the most common shape remains a box-like enclosure. Custom carrying cases are ordered by businesses or manufacturers who wish to protect their product but who also require a specially made case.

Some custom carrying cases are manufactured using CNC machining which minimizes errors because computers control the machining instead of human operators. This allows the parts to be machined with high tolerances and precision. CNC machining may be used with a variety of materials; however, each material has its own fabrication and assembly requirements.

Metal carrying cases are made from sheets of metal that have been fastened onto a metal frame. Raw metal is melted together until uniform then cooled into slabs which are pressed through a series of rollers until it reaches the desired thinness. The sheets are then bent into the customized shape and dimension and welded or screwed together. The metal frame is usually constructed of extruded aluminum or steel. The corners are often reinforced with metal panels for longer life.

Plastic shipping cases are molded through a number of processes including blow molding, injection molding and rotational molding. FRP plastics have fibers that are first woven, knit, braided or stitched together before bonding to the surface of the matrix, a tough plastic.

Other customizable features include heavy duty swivel casters, twist latches, spring loaded handles, rubber gaskets around the doors for water resistance, recessed latches to meet military standards, molded lugs for secure stacking, shock mounts, enhanced and fortified steel or aluminum framing, buckles, straps, molded tracks for easy stacking or many other options.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

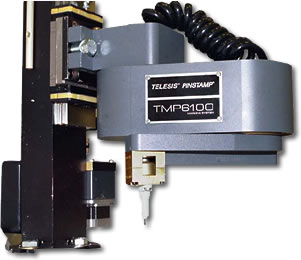

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services