Hard cases are traditionally been fairly simple in design though custom and specialty cases are also widely used. Many are shaped like boxes and have packing material inside such as packing peanuts, heavy foam, special racks, shelving or a lining made of paper, foam, rubber, wood shavings, plastic or other materials. Read More…

One of the top carrying case suppliers, Princeton Case West provides quality carrying cases, custom cases, shipping cases, plastic cases, aluminum cases, tool cases, computer cases, instrument cases, transit cases and ATA cases. Princeton Case West offers custom foam inserts for varying applications. From design to delivery, Princeton Case West offers the complete package at affordable pricing.

Our cases come in various configurations such as soft sewn cases, hard cases, model cases, exhibit cases, and more. We are experts in contract sewing and there is no project too complex for our experts. With manufacturing experience dating back to 1994 we are confident we can provide you with a top of the line custom carrying case.

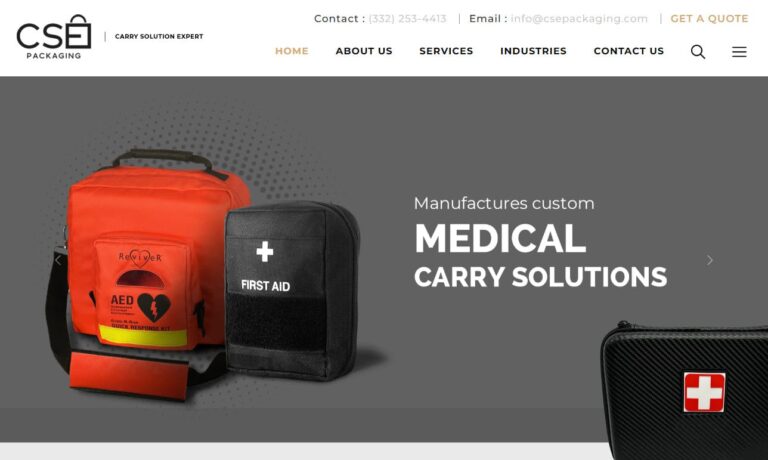

At CSE Packaging, we stand as a trusted leader in the realm of carrying cases, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

ZERO Manufacturing prides itself on the production of custom carrying cases made not only to hold valuable equipment but to protect it with state-of-the-art technology. As premium carrying case suppliers, ZERO Manufacturing offers diverse carrying cases including custom cases, plastic cases, ATA cases, transit cases, aluminum cases, instrument cases, computer cases, shipping cases and tool cases.

Ameripack is a leading manufacturer and distributor of carrying cases, Rack Mount and Rotational molded cases. Ameripack can fulfill custom foam inserts, panel mount applications, and since 1989 we have provided our customers with Cases that fit their applications. Over 300 sizes; 6,000 cases in stock!

More Hard Case Manufacturers

Hard Cases: Essential Protection and Customization Solutions

Hard cases are engineered storage and transport solutions designed to safeguard valuable, sensitive, or fragile equipment from impact, environmental exposure, and unauthorized access. Whether used in industrial, commercial, or personal applications, hard carrying cases offer a blend of durability, security, and organization. As a top choice for protective packaging, hard cases are utilized across diverse industries, each with unique requirements and use cases. If you are looking for information that will help you understand how to choose the right hard case for your business or personal needs, this guide will help you evaluate key decision factors, customization options, and industry-specific applications.

What Are Hard Cases Used For?

Hard cases serve as robust protective enclosures for a vast array of objects. Some are designed like briefcases, featuring internal pockets, dividers, and organizers for efficient storage and accessibility. Others are engineered for heavy-duty industrial or commercial use, boasting reinforced exteriors and advanced locking mechanisms. The automotive, athletics, business, outdoor, travel, medical, emergency, optical, and music industries all depend on hard cases to protect and organize:

- Camping equipment and outdoor gear

- First aid supplies and emergency response kits

- Hearing aids and optical devices

- Electronics (such as laptops, monitors, projectors, and audio/video equipment)

- Audio production gear and musical instruments

- Firearms and tactical equipment

- Medical supplies and diagnostic tools

- Important documents, passports, and sensitive paperwork

- Jewelry, collectibles, and valuables

- Tools, meters, and specialized instruments

Are you searching for a specific type of hard case, such as a custom instrument case, protective laptop case, or hard-sided travel luggage? Explore our industry-leading instrument case manufacturers for tailored solutions.

Benefits of Hard Cases: Why Choose Hard-Sided Protection?

Choosing a hard case over a soft case or simple bag provides distinct advantages, particularly for items that require maximum protection and secure transport. Here are some of the key benefits:

- Impact Resistance: Hard cases are designed to absorb shocks and prevent damage from drops, bumps, or rough handling, making them ideal for shipping delicate or high-value equipment.

- Weatherproof & Watertight: Many hard cases feature rubber gaskets and weather-sealed construction, providing protection from moisture, dust, and contaminants—essential for outdoor, marine, and field applications.

- Enhanced Security: Reinforced locks, tamper-evident seals, and steel or aluminum framing help deter theft and prevent unauthorized access.

- Customizable Interiors: Foam inserts, dividers, and pockets can be tailored to fit your equipment, ensuring a snug fit and reducing movement during transit.

- Organizational Efficiency: Internal organizers, zippered pockets, and labels make it easy to access and manage components, tools, or supplies.

- Longevity: Hard cases are built to withstand years of use, offering a durable solution that reduces replacement costs over time.

- Professional Appearance: Sleek, branded hard cases present a polished image for businesses and professionals attending trade shows, sales meetings, or presentations.

Wondering how hard cases compare to soft cases or other types of packaging? Learn more about the differences between hard cases and soft cases to determine the best solution for your application.

Key Materials and Manufacturing Methods for Hard Cases

The performance, durability, and cost of a hard case are largely determined by its construction materials and fabrication methods. The choice of materials impacts everything from weight and strength to environmental resistance and price point. Here are the primary materials used in hard case manufacturing:

- Plastic Cases: Plastic hard cases are lightweight, corrosion-resistant, and available in a range of colors and finishes. Common plastics include ABS, polycarbonate, polypropylene, and FRP (Fiber Reinforced Plastic). These materials are selected for their impact resistance, flexibility, and ease of molding into complex shapes.

- Aluminum Cases: Aluminum hard cases offer a premium look and exceptional strength-to-weight ratio. They are often used for electronics, optics, and audiovisual equipment, providing EMI/RFI shielding as well as physical protection. Aluminum resists rust and can be anodized for additional durability and aesthetics.

- Steel Cases: For the ultimate in ruggedness and security, steel hard cases are chosen for industrial, military, and law enforcement use. Reinforced steel corners and heavy-duty latches withstand harsh conditions and deter forced entry.

- Composite & Hybrid Cases: Some hard cases utilize a combination of materials—such as wood cores with plastic or metal exteriors—for unique blends of strength, appearance, and cost efficiency.

Hard cases are fabricated using several advanced manufacturing processes, each with distinct advantages:

- Injection Molding: Hot plastic is injected into a precision mold, then cooled to create rigid, seamless shells. This process is ideal for high-volume production of consistent, lightweight cases.

- Blow Molding: Air pressure forms hollow plastic parts by inflating hot plastic into a mold, yielding durable and lightweight cases often used for medical or emergency kits.

- Rotational Molding: Plastic resin is rotated inside a heated mold, resulting in a uniform, robust shell with no seams or weak points—perfect for heavy-duty applications.

- FRP Layup: Fiber Reinforced Plastic cases require fibers to be woven, braided, or stitched, then bonded to a tough plastic matrix, combining flexibility with extraordinary impact resistance.

- Sheet Metal Fabrication: Thick metal sheets are fastened to frames, with reinforced corners and welded seams to enhance security and performance under pressure.

Curious about which hard case material and manufacturing method is best for your needs? Contact our experts or request a quote to discuss your requirements.

Customization Options: Tailoring Hard Cases for Your Application

One of the greatest advantages of hard cases is their ability to be customized for specific contents and use cases. Custom hard cases can be designed from the ground up or adapted from standard models with the following enhancements:

- Custom Foam Inserts: Precision-cut foam cradles your equipment, tools, or instruments, protecting them from movement and impact.

- Dividers and Organizers: Modular dividers, mesh pockets, and trays create tailored compartments for cables, accessories, or consumables.

- Branding and Labeling: Screen printing, embossing, and custom color choices reinforce your brand and facilitate easy identification.

- Specialty Hardware: Spring-loaded handles, twist latches, security locks, and heavy-duty casters enhance usability and mobility.

- Environmental Protection: Rubber gaskets, watertight seals, and anti-corrosive finishes help protect contents from the elements.

- Shock Mounts and Suspension Systems: Advanced mounting systems isolate sensitive equipment from vibration and sudden jolts.

- Custom Sizing and Shape: Cases can be manufactured to fit specific dimensions, accommodating even irregularly shaped items.

Looking for a case to protect your unique equipment? Get a custom quote for hard cases with foam inserts or specialized hardware to ensure the perfect fit and maximum protection.

Industry-Specific Hard Case Applications

While hard cases are versatile, certain industries have unique requirements that drive specialized designs. Here’s how hard cases serve critical roles in different markets:

Medical & Emergency Hard Cases

Hard cases for medical devices, diagnostics, and emergency supplies are engineered for rapid deployment and sterilization. These cases often feature:

- Antimicrobial surfaces and easy-to-clean interiors

- Clearly labeled compartments for medications and equipment

- Integrated wheels and ergonomic handles for quick mobility

- Weatherproof seals to protect against contamination

Military, Law Enforcement & Tactical Cases

Military-grade hard cases are designed to withstand extreme conditions, including water, dust, shock, and impact. Common features include:

- Reinforced corners and steel hardware

- Custom foam for firearms, optics, and communications gear

- Lockable, tamper-evident latches

- Stackable, modular designs for efficient transport

Industrial, Scientific & Technical Hard Cases

Protecting sensitive instruments, meters, and calibration devices requires cases with:

- Electrostatic discharge (ESD) protection

- Precise, custom-cut foam for fragile sensors

- Accessibility for on-site calibration and maintenance

- Heavy-duty wheels and handles for rugged environments

Music, Audio & Visual Equipment Cases

Musicians, audio engineers, and event professionals rely on hard cases to transport:

- Guitars, keyboards, and band instruments

- Mixers, microphones, and AV peripherals

- Cables, stands, and lighting gear

- Shock-absorbent interiors for delicate equipment

Want to see examples of industry-specific hard cases? Browse our gallery of instrument and equipment case solutions.

How to Choose the Right Hard Case: Key Decision Factors

When evaluating hard cases for purchase, it’s important to consider several factors to ensure you select the optimal solution for your application. Here are some questions to guide your decision-making process:

- What are the size, weight, and shape requirements for the items to be stored?

- Will the case be exposed to harsh environments (moisture, dust, temperature extremes)?

- Does your application require mobility features such as wheels or telescoping handles?

- How important is security (locks, tamper resistance, concealment)?

- Do you need custom branding or specific colors for identification?

- Is quick access or organized storage a priority?

- What are your budget and lead time constraints?

If you’re unsure how to balance these factors, request a consultation with a hard case specialist to discuss your unique requirements and receive personalized recommendations.

Hard Case Trends and Innovations

The hard case industry continues to evolve with new materials, technologies, and smart features. Some recent trends include:

- Lightweight composite cases that offer the strength of metal with reduced weight

- IoT-enabled cases with built-in GPS tracking and environmental monitoring

- Modular case systems for scalable storage and rapid deployment

- Eco-friendly materials and recyclable plastics for sustainable solutions

- Advanced foam cutting and 3D scanning for perfectly tailored interiors

- Antimicrobial coatings for medical and food industry cases

Looking for the latest in hard case technology? Explore our innovation hub to see what’s new in protective case design and manufacturing.

Frequently Asked Questions About Hard Cases

- What’s the difference between a hard case and a soft case?

A hard case has a rigid outer shell (plastic, metal, or composite) offering superior impact and environmental protection, whereas a soft case uses flexible fabrics, ideal for lightweight or less fragile items. - Can I order custom hard cases in small quantities?

Yes—many manufacturers offer low minimum orders for custom hard case solutions, including foam inserts and specialty hardware. - Are hard cases waterproof?

Many hard cases are designed to be watertight or weatherproof, but always check IP ratings and gasket features before purchase. - How do I clean and maintain a hard case?

Most hard cases can be wiped with a damp cloth and mild detergent. For medical or food applications, look for cases with antimicrobial liners. - Can hard cases be repaired if damaged?

Depending on the material, many hard cases can be repaired with replacement hardware, foam, or patch kits. Check with your manufacturer for repair options.

Get Started: Find the Best Hard Case for Your Needs

Ready to invest in a durable, reliable hard case for your sensitive equipment, tools, or valuables? Whether you need a custom instrument case, plastic case, or a heavy-duty industrial hard case, we can help you source the ideal solution. Contact us today to request a quote, compare product options, or discuss your project with our experts.

Still researching? Check out our in-depth guides on:

- Instrument Case Selection

- Plastic Hard Cases: Materials & Applications

- Understanding Custom Foam Inserts for Hard Cases

- How to Maintain and Clean Your Hard Case

- Comparing Hard Case Brands and Manufacturers

Stay informed about the latest protective case solutions and industry news by subscribing to our newsletter or following us on social media. Your equipment deserves the best—choose hard cases for unmatched protection, organization, and peace of mind.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

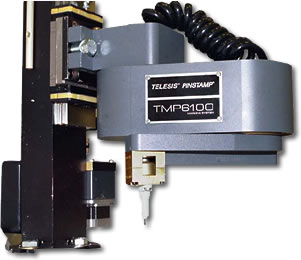

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services